Free TIG welding ebook course with free certification. Master torch control, filler technique, and clean welds on steel, stainless, and aluminum.

Course content

TIG Welding Fundamentals: Safety, Workspace Setup, and Cleanliness Standards

2TIG Torch Anatomy and Consumables for Clean Welds

3Shielding Gas Basics: Argon Flow, Coverage, and Oxidation Prevention

4Tungsten Types, Selection, and Preparation for Stable Arc Control

5Machine Setup: Polarity, AC Balance Concepts, and Amperage Ranges for Beginners

6Arc Starts, Arc Length, and Torch Angle: The Foundations of TIG Weld Appearance

7Hand Coordination: Filler Rod Feeding Techniques and Puddle Timing

8Building Clean Beads on Mild Steel: Heat Control and Bead Consistency

9Clean TIG on Stainless Steel: Color Control, Sugaring Avoidance, and Crack Prevention

10TIG on Aluminum Fundamentals: Oxide Management, AC Technique, and Puddle Control

11Joint Fit-Up and Tacking for TIG Welding: Butt, Lap, and Fillet Practice

12Contamination, Porosity, Oxidation, and Cracking: Diagnosing and Fixing Common TIG Problems

13Finishing Skills: Crater Fill, Stop/Restart Control, and Bead Blending for Clean Results

Course Description

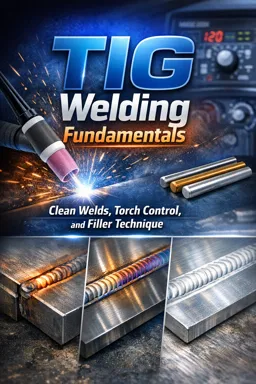

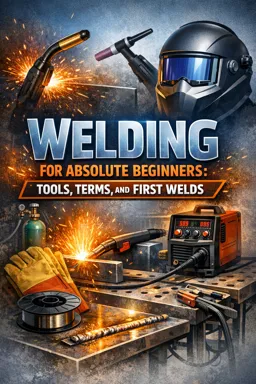

TIG Welding Fundamentals: Clean Welds, Torch Control, and Filler Technique is a practical ebook course built for anyone who wants to create clean TIG welds with confident torch handling and consistent filler technique. Designed within professional courses and focused on welding, it helps you set up correctly, work safely, and develop habits that lead to strong, good looking results on real materials.

You will learn how a clean workspace, proper preparation, and correct consumable choices directly affect weld quality. The course explains TIG torch anatomy, shielding gas fundamentals, and how argon flow and coverage protect the puddle from oxidation. You will also understand tungsten selection and preparation for stable arc control, plus essential machine setup concepts like polarity, AC balance, and beginner friendly amperage ranges so your settings match the metal and joint.

Progressive practice is emphasized, starting with arc starts, steady arc length, and torch angle so you can control heat and appearance from the beginning. As coordination improves, you will refine filler rod feeding, puddle timing, and travel speed to build clean beads with repeatable consistency. You will apply these TIG welding fundamentals to mild steel for heat control, then move into stainless steel where color control, sugaring avoidance, and crack prevention matter, and finally develop TIG welding on aluminum skills with oxide management, AC technique, and puddle control.

The course also connects technique to real workshop outcomes by improving joint fit up and tacking for butt, lap, and fillet joints, helping you reduce distortion and maintain alignment. When problems show up, you will learn to diagnose contamination, porosity, oxidation, and cracking, then correct the root cause through better preparation, torch control, gas coverage, and parameter adjustments. Finishing skills like crater fill, stop and restart control, and bead blending help you deliver professional looking results that hold up under use.

Start this free TIG welding ebook course today and build the foundation for cleaner welds, better control, and more reliable performance in shop and field work.

This free course includes:

13 content pages

Digital certificate of course completion (Free)

Exercises to train your knowledge

100% free, from content to certificate

Ready to get started?

In the app you will also find...

Over 5,000 free courses

Programming, English, Digital Marketing and much more! Learn whatever you want, for free.

Study plan with AI

Our app's Artificial Intelligence can create a study schedule for the course you choose.

From zero to professional success

Improve your resume with our free Certificate and then use our Artificial Intelligence to find your dream job.

You can also use the QR Code or the links below.