What “Duration Estimating” Means in Residential and Small-to-Mid Commercial Work

Duration estimating is the process of predicting how long each scheduled activity will take in working time (days, hours, shifts) given the crew, tools, access, productivity, and jobsite conditions you expect. In residential and small-to-mid commercial projects, duration estimating is rarely a purely mathematical exercise. It is a practical forecast that must reconcile field reality: small crews, limited staging space, frequent trade stacking, inspections that gate progress, and material lead times that can turn a one-day task into a one-week calendar impact.

Duration is not the same as effort. Effort is labor hours (e.g., 80 labor-hours). Duration is how many working days it takes with a specific crew and work pattern (e.g., 2 carpenters for 5 days at 8 hours/day). Two activities can have the same effort but different durations depending on crew size, overtime, access, and sequencing.

For residential and small-to-mid commercial work, duration estimating should be accurate enough to support commitments (start dates, inspection bookings, trade coordination) while remaining simple enough to update weekly. The goal is a schedule that behaves like the jobsite: it should show where time is truly consumed, where handoffs occur, and where variability is highest.

Key Inputs That Drive Realistic Durations

1) Quantity and production rate

Most field durations can be estimated from quantities and production rates. Example: 1,200 SF of drywall hang at 400 SF per person per day. With a 2-person crew, expected production is 800 SF/day, so hanging is about 1.5 days. You then decide whether to round to 2 days to reflect mobilization, layout, and punch.

2) Crew composition and continuity

Small projects often use “floating” crews that split time across jobs. A duration estimate should reflect whether the crew will be dedicated or intermittent. A task that is 2 days of effort can become 5 calendar days if the crew is only on site half-days or every other day. When you estimate duration, explicitly assume crew continuity (e.g., “2-person crew, dedicated, full days”).

- Listen to the audio with the screen off.

- Earn a certificate upon completion.

- Over 5000 courses for you to explore!

Download the app

3) Access, staging, and working hours

Residential remodels and occupied commercial spaces introduce access windows, noise restrictions, elevator reservations, and limited laydown areas. These constraints reduce effective productivity. If work can only occur 9 a.m.–3 p.m., your “8-hour day” production rate is not applicable. Convert to effective hours and adjust.

4) Learning curve and rework risk

Custom details, first-time assemblies, and coordination-heavy installations (e.g., MEP in tight ceilings) have a learning curve. Early units take longer; later units go faster. For small-to-mid commercial tenant improvements, the first restroom core or first office bay often sets the pace. Consider estimating the first unit separately from repeats.

5) Inspection and approval gates

Inspections, owner walk-throughs, and AHJ sign-offs can dominate calendar time. The field work might be one day, but the gate can take three. Treat gates as duration drivers by estimating the time from “ready” to “approved,” not just the time to perform the work. This is especially important for rough inspections, fire alarm testing, and utility releases.

6) Material availability and “ready-to-work” conditions

Duration estimating must reflect whether the activity can proceed uninterrupted. If cabinets are “expected next week,” the installation duration is irrelevant until delivery is confirmed. For small projects, a single missing component (valve trim, specialty light, storefront hardware) can stall an entire area. Build durations assuming materials are on hand; separately plan the procurement and delivery windows so the schedule reflects readiness.

Common Duration Estimating Methods (and When to Use Them)

Analogous estimating (reference-based)

Use durations from similar past projects and adjust for size and complexity. This is fast and often accurate for repeated work: single-family homes of similar design, small retail build-outs, or standard office TI. The key is to document what “similar” means (square footage, number of rooms, ceiling type, finish level, crew size).

Parametric estimating (quantity × rate)

Use measurable quantities and production rates. This is the workhorse method for framing, drywall, painting, flooring, and sitework. It is transparent and easy to defend when questioned by owners or subs.

Three-point estimating (optimistic, most likely, pessimistic)

Use when uncertainty is high: selective demolition, underground utilities, structural modifications, or complex inspections. You estimate three durations and compute an expected value (often a weighted average). Even if you do not compute a formal expected value, the exercise forces you to acknowledge variability and plan buffers where they belong.

Expert judgment with field validation

In small-to-mid commercial work, subcontractors often provide durations as part of their planning. Use their input, but validate it against access constraints, inspection lead times, and trade stacking. Ask: “How many workers? How many hours per day? What assumptions about preceding work and material availability?”

A Practical Step-by-Step Workflow for Estimating Activity Durations

Step 1: Define the unit of time and rounding rules

Decide whether your schedule will use hours, half-days, or days. Residential schedules often work well in days with half-day granularity for inspections and small tasks. Small-to-mid commercial schedules may use days, with select tasks in hours if night work or shutdown windows matter.

Set rounding rules to avoid false precision. Example rules: round field tasks to the nearest half-day; round procurement/approval gates to full days; never schedule a task shorter than 0.5 day unless it is a milestone.

Step 2: Choose the estimating method per activity

Not every activity needs the same rigor. Use parametric estimating for production-driven work, analogous for repeated scopes, and three-point for uncertain scopes. Document the method in your notes so updates are consistent.

Step 3: Establish the crew and productivity assumption

Write the crew size and expected productivity next to the duration. Example: “Drywall hang: 2 hangers @ 800 SF/day combined.” If the crew changes, you can quickly recalculate duration instead of guessing.

Step 4: Convert effort to duration (and check feasibility)

Compute duration = quantity ÷ (rate × crew) and then adjust for setup, mobilization, and site constraints. Check feasibility: Can that crew physically work in the space? Can multiple crews work without interference? In small spaces, adding labor does not reduce duration proportionally due to congestion.

Step 5: Add realistic allowances for interruptions

Residential and small commercial work is interruption-prone: client decisions, trade callbacks, partial deliveries, and inspection scheduling. Add allowances where they occur, not as a blanket “padding” across all tasks. For example, add time between “rough complete” and “rough inspection passed” if the AHJ typically books 2–3 days out.

Step 6: Cross-check with trade stacking and area flow

Even without revisiting logic-building concepts, you should sanity-check that durations align with how areas flow. If painting is estimated at 1 day for a 6,000 SF office with multiple coats and cut-in, that is likely unrealistic. Compare to typical daily production and the number of rooms/edges.

Step 7: Calibrate using historical actuals

After each project, capture actual durations for key activities (framing, rough-in, drywall, flooring, punch). Store them with context: project type, crew size, constraints. Over time, your duration estimates become faster and more accurate.

Residential-Specific Considerations

Remodeling vs. new build

Remodeling durations are dominated by unknowns and access limitations. Selective demolition can reveal hidden conditions (rot, undersized framing, unpermitted work). For remodels, use three-point estimating for demo and early rough-in, and include time for discovery and decision-making. New builds are more production-driven; parametric rates apply more reliably.

Owner selections and decision latency

In residential work, finishes are often selection-driven (tile patterns, fixtures, paint colors). The installation duration might be short, but waiting for decisions can stop progress. Treat “selection complete” as a readiness condition and estimate the time needed for review cycles if the owner is indecisive or remote.

Small crews and multitasking

Residential GCs often run lean crews that self-perform multiple scopes. A carpenter crew might frame, install doors, and do punch. Duration estimates must reflect task switching and mobilization. A “1-day” door install can become 3 days if the crew is also handling deliveries, site protection, and client walk-throughs.

Inspections and utility coordination

Residential inspections can be quick but scheduling can be unpredictable. Utility releases (gas, power) can add calendar time. Estimate the gate time based on local experience: some jurisdictions offer next-day inspections; others require 3–5 days.

Small-to-Mid Commercial Considerations

Working in occupied buildings

Occupied commercial work often requires off-hours, noise control, dust containment, and phased turnover. Productivity drops due to setup and teardown (containment walls, negative air machines, daily cleanup). Build that into durations: a task that is 3 days in an empty space may be 5–6 days in an occupied environment.

Permitting, inspections, and third-party testing

Commercial projects frequently involve special inspections, fire alarm verification, sprinkler inspections, and commissioning activities. These are schedule drivers with external dependencies. Estimate durations for the entire cycle: prepare, test, correct deficiencies, retest, and obtain sign-off.

Long-lead items that affect field durations

RTUs, switchgear, storefront, elevators, and specialty lighting can dictate when areas can be closed up. While procurement is separate from field installation, the field duration estimate should reflect realistic installation windows, including rigging, shutdowns, and inspections.

Trade stacking and congestion

In small-to-mid commercial interiors, multiple trades work in the same ceiling and corridor spaces. Congestion reduces productivity. If you estimate each trade at full productivity as if they have exclusive access, the combined plan will be optimistic. Adjust durations or plan work by zones to reduce stacking.

How to Build and Use Production Rates (Without Overcomplicating)

Production rates are most useful when they are simple, consistent, and tied to your crews. Start with a small library of rates for common activities and refine them with actuals. Keep rates in units that match how you buy and build: SF/day for drywall and paint, LF/day for base and framing, fixtures/day for trim-out, rooms/day for punch and cleaning.

Example production rate table (starter set)

- Metal stud framing: 250–400 SF of wall area per person per day (varies by height, openings, and track complexity)

- Drywall hang: 300–500 SF per person per day (varies by ceiling work, board size, and access)

- Drywall finish: 200–400 SF per person per day (multiple coats, sanding, and drying time affect calendar)

- Interior paint (walls): 1,500–3,000 SF per painter per day for one coat in open areas; less in cut-in heavy rooms

- LVT flooring: 400–800 SF per installer per day depending on prep and pattern

- ACT ceiling: 300–600 SF per installer per day depending on grid complexity and above-ceiling coordination

Use these as starting points, then adjust for your project’s constraints. The point is not to have perfect rates; it is to have a rational basis for durations and a way to update them when conditions change.

Calendar Time vs. Working Time: Drying, Curing, and Waiting

Many activities in residential and commercial interiors include “non-working” time that still consumes calendar days: concrete cure, thinset cure, paint dry, drywall mud dry, waterproofing cure, acclimation of flooring, and inspection booking. If you only estimate labor time, your schedule will compress unrealistically.

Handle this by explicitly estimating the waiting component as part of the activity duration or as a separate “cure/dry” activity, depending on how you track work. For example, tile installation might be 2 days of labor plus 1 day of cure before grout, and another day before heavy traffic. Similarly, drywall finishing may require multiple visits with drying time between coats.

Worked Examples

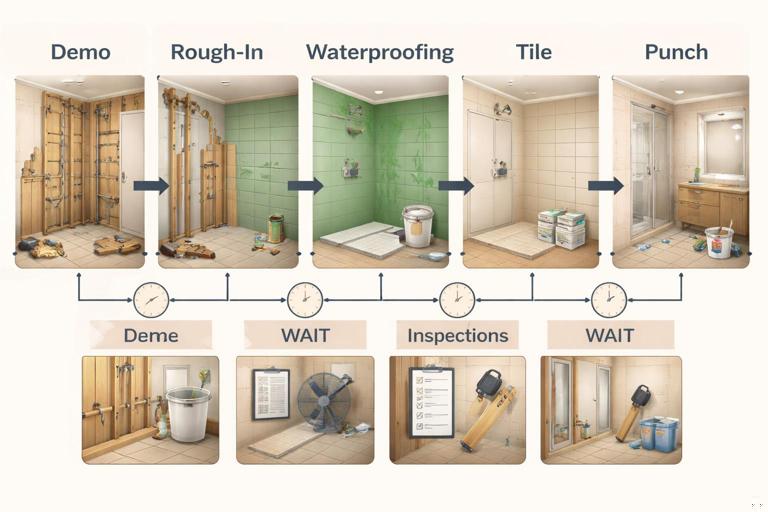

Example 1: Residential bathroom remodel (single bath)

Assume a 60 SF bathroom with tub/shower surround tile, new vanity, and standard finishes. The goal is to estimate realistic durations for key activities using simple assumptions.

Selective demo: optimistic 0.5 day, most likely 1 day, pessimistic 2 days (hidden damage). Expected planning duration: 1–1.5 days depending on risk tolerance.

Rough framing adjustments: small scope, but includes blocking and niche framing. Estimate 0.5–1 day with a carpenter.

Plumbing rough-in: 1 plumber, 1 day if straightforward; 2 days if venting changes or access is tight. Use 1–2 days.

Electrical rough-in: 1 electrician, 0.5–1 day depending on fan/light changes and panel capacity.

Insulation and vapor management: 0.5 day.

Drywall hang and finish: hang 0.5 day; finish requires multiple coats. Labor might be 1 day total, but calendar could be 3–4 days due to drying and return trips. Estimate 3 days calendar if you want a realistic plan.

Waterproofing (shower): 0.5 day install + 1 day cure (per product requirements). Estimate 1.5–2 days calendar.

Tile install: walls 80–120 SF plus floor 60 SF. If installer produces 80–120 SF/day in a small detailed space, estimate 2 days set + 1 day cure + 0.5 day grout. Total 3.5–4 days calendar.

Paint: 0.5 day including prep and two coats in a small room (often split across days). Estimate 1 day calendar to reflect dry time.

Trim-out (plumbing/electrical): 0.5 day each, but coordinate availability. If the same subs cannot return immediately, calendar duration may be 2–3 days across both trades.

Punch and clean: 0.5–1 day.

Notice how several tasks have small labor effort but larger calendar durations due to curing, drying, and return scheduling. This is where residential schedules often fail if durations are estimated only from labor.

Example 2: 6,000 SF small office tenant improvement

Assume new partitions, ACT ceilings, lighting changes, paint, carpet tile, and a small breakroom. Use parametric rates and adjust for congestion and inspections.

Metal stud framing: 2,000 SF of wall area. Rate 300 SF/person/day. Crew of 2: 600 SF/day. Base duration: 3.3 days. Add layout/coordination and door frames: round to 5 days.

In-wall rough-in (MEP): depends on density. If electrical is moderate and data is separate, estimate 4–6 days for electrical rough, 2–3 days for low voltage rough, 2–4 days for plumbing if only breakroom. Adjust upward if working hours are restricted.

Inspections (rough): field readiness may be 0 days, but booking and corrections can be 2–4 days calendar. Estimate 3 days calendar for the full cycle if the AHJ is busy.

Drywall hang: 2,000 SF wall area × 2 sides = 4,000 SF board area (simplified). Crew of 3 at 400 SF/person/day = 1,200 SF/day. Base: 3.3 days. Add ceilings/soffits and congestion: 4–5 days.

Drywall finish: same area, but finishing is slower and includes drying. Crew of 2 at 300 SF/person/day = 600 SF/day labor suggests ~7 days of effort; calendar may be 8–10 days due to coats and sanding cycles. Estimate 9 days calendar.

ACT ceiling: 6,000 SF at 500 SF/installer/day. Crew of 2: 1,000 SF/day. Base: 6 days. If above-ceiling coordination is heavy, estimate 7–8 days.

Paint: walls and ceilings. If total paintable area is 18,000 SF and rate is 2,000 SF/painter/day per coat, with 2 painters and two coats, effort suggests 9 days. With efficient sequencing and spray/roll mix, you might plan 7–9 days. Use 8 days unless the space is very open.

Carpet tile: 5,000 SF at 600 SF/installer/day. Crew of 2: 1,200 SF/day. Base: 4.2 days. Add floor prep and pattern alignment: 5–6 days.

Electrical trim and lighting: if 120 fixtures and devices combined, and a 2-person crew trims 40–60 devices/fixtures per day depending on complexity, estimate 3–4 days plus testing and corrections.

Fire alarm testing/inspection: even if field work is 1 day, include 2–3 days for scheduling, testing, and sign-off cycle.

This example shows how commercial durations often expand around finishing cycles (drywall finish, paint) and external gates (inspections, testing). The most common estimating error is treating these as purely labor-driven tasks.

Adjusting Durations for Real-World Conditions

Factor 1: Crew size changes (and diminishing returns)

Doubling the crew does not always halve the duration. In tight spaces (bathrooms, small corridors, occupied suites), congestion and coordination reduce efficiency. A simple adjustment is to apply a diminishing returns factor when adding labor. Example: if you add 50% more labor, assume only a 25–35% duration reduction unless the work area is large and unconstrained.

Factor 2: Weather and exterior work

For small commercial and residential exterior work (roofing, siding, concrete flatwork), weather can dominate. Instead of adding random padding, estimate durations based on workable days. If your region averages 3 rain days per month in the season, incorporate that into exterior task durations or plan weather allowances around critical exterior milestones.

Factor 3: Rework and punch

Punch is not a single event; it is a cycle. Estimate punch duration based on area size and finish level, and include time for trade callbacks. A practical approach is to estimate punch as a percentage of finishing time (e.g., 5–10% for straightforward work, 10–20% for high-end finishes or tight tolerances), then convert that to days based on crew availability.

Factor 4: Submittals and shop drawings that affect field time

Even on small-to-mid commercial jobs, shop drawings (storefront, millwork, steel) can affect when field work can proceed. While the administrative process is separate from installation, it impacts the “ready-to-work” date. If you routinely see delays here, include realistic review and revision durations so field installation is not scheduled optimistically.

Documenting Duration Assumptions So Updates Are Fast

Duration estimates become valuable when they are traceable. For each major activity, capture a short note with: quantity, production rate, crew size, access constraints, and gate times. This allows you to update durations quickly when conditions change (crew reduced, area opened up, inspection backlog). It also improves communication with subs and owners because you can explain the basis of the schedule without debating opinions.

Example activity note format (keep it short): Activity: Paint Level 4 finish, Suite A Basis: 18,000 SF paintable area; 2 painters; 2 coats; 2,000 SF/painter/day/coat Adjustments: occupied building, daily setup/cleanup (+1 day) Duration used: 8 working daysTypical Estimating Pitfalls (and How to Avoid Them)

Using “best day ever” productivity as the standard

Crews remember their fastest day, not their average. Base durations on average production under expected conditions, then adjust for known constraints. If you want to be aggressive, do it intentionally and document what must go right (dedicated crew, materials staged, no rework).

Ignoring mobilization and demobilization

Small projects have high relative overhead per task: setup, protection, tool movement, cleanup, and coordination. Add time for these, especially in occupied spaces and remodels.

Assuming perfect trade availability

In residential and small commercial work, subs may not return the next day. A 0.5-day trim-out can take a week of calendar time if it is squeezed between other jobs. Estimate durations with realistic return windows or plan activities to consolidate work into fewer mobilizations.

Forgetting drying/curing and inspection booking time

These are the most common sources of schedule drift. Treat them as real duration drivers and estimate them based on product requirements and local inspection lead times.

Over-fragmenting tasks into tiny durations

If you break work into too many small activities, duration estimating becomes noise and updates become burdensome. Keep activities at a level where durations are meaningful and trackable (often 0.5–5 days for residential, 1–10 days for small commercial), while still reflecting key gates and handoffs.