Why AFCI/GFCI Coordination Matters in Smart Homes

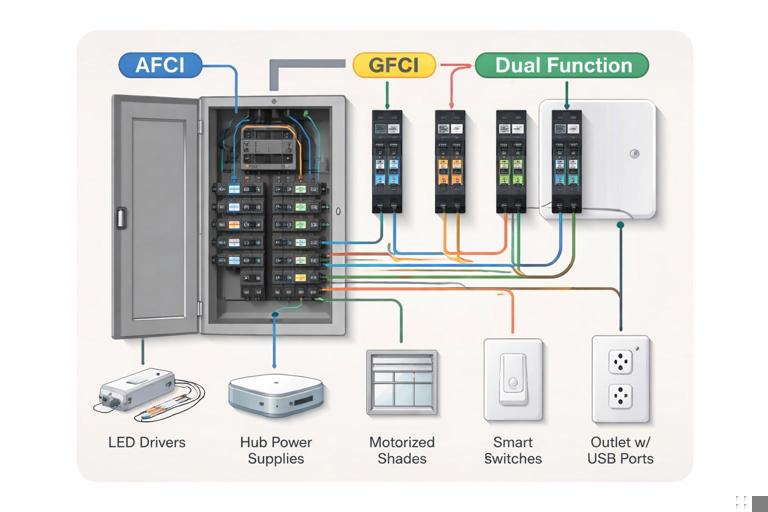

Smart homes concentrate many electronic loads on branch circuits: LED drivers, power supplies for hubs, motorized shades, smart appliances, and plug-in adapters. These loads can introduce leakage current, high-frequency noise, and non-sinusoidal waveforms that interact with protective devices. In modern residential work, you are often required to provide both arc-fault protection (AFCI) and ground-fault protection (GFCI) depending on location and circuit type. Coordination means selecting and installing protective devices so they meet code requirements while minimizing nuisance trips and ensuring that a fault clears in a predictable, serviceable way.

From a workflow standpoint, coordination also means you can troubleshoot efficiently: you should be able to identify whether a trip is caused by a true ground fault, an arc signature, an overcurrent, a shared-neutral error, or a device compatibility issue. A code-minded workflow treats protection as part of the system design and commissioning process rather than an afterthought.

Concepts You Must Keep Straight: What Each Device Is Actually Detecting

GFCI: imbalance, not “ground current”

A GFCI device compares current leaving on the ungrounded conductor(s) to current returning on the grounded conductor (neutral). If the difference exceeds the trip threshold (typically 4–6 mA for personnel protection devices), it opens the circuit. The current causing the imbalance may be flowing through equipment grounding conductors, building steel, plumbing, damp materials, or a person. The key point for coordination: any leakage to ground anywhere downstream of the sensing point can trip it, including cumulative leakage from multiple electronic loads.

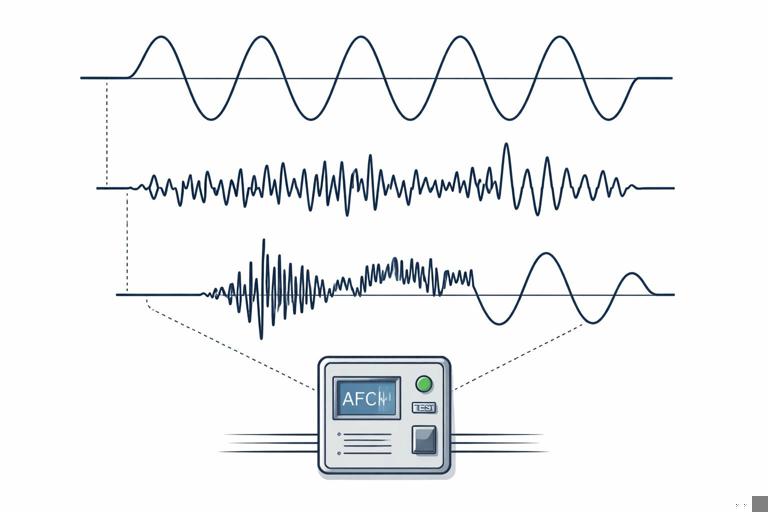

AFCI: arc signatures, plus often additional functions

An AFCI looks for waveform patterns consistent with arcing faults (series and/or parallel arcs depending on type). Modern “combination-type” AFCIs are common in dwelling units. Many AFCI breakers also incorporate ground-fault sensing at a higher threshold (equipment-level ground-fault detection) and may be more sensitive to certain noise patterns. Coordination issue: some loads (certain motors, older dimmable LED drivers, vacuum cleaners, treadmills, or devices with brushes) can resemble arc signatures during normal operation, especially at startup or under varying load.

Dual-function AFCI/GFCI

A dual-function breaker provides both arc-fault and personnel-level ground-fault protection in one device. This often simplifies coordination because there is a single sensing point and a single trip mechanism to interpret. However, it can also concentrate troubleshooting into one device, so your labeling and commissioning notes become more important.

- Listen to the audio with the screen off.

- Earn a certificate upon completion.

- Over 5000 courses for you to explore!

Download the app

Where “coordination” shows up in the field

- Stacking protection: e.g., an AFCI breaker feeding a downstream GFCI receptacle, or a GFCI breaker feeding downstream AFCI devices (less common). Stacking can be code-allowed in some situations but can increase nuisance tripping and complicate troubleshooting.

- Shared neutrals and multi-wire branch circuits (MWBCs): neutral current paths and sensing windows matter. Incorrect neutral routing is a top cause of immediate trips.

- Equipment leakage aggregation: multiple plug-in power supplies and EMI filters can add up to a trip threshold even when each device is “normal.”

- Miswiring and bootleg neutrals/grounds: any neutral-to-ground connection downstream of a GFCI sensing point can cause trips or erratic behavior.

Code-Minded Selection: Choosing a Protection Strategy That Stays Serviceable

Always verify the currently adopted code cycle and local amendments, but the workflow below keeps you aligned with typical residential requirements while reducing callbacks.

Strategy A: Dual-function breaker (often best for smart-home branch circuits)

Use a dual-function AFCI/GFCI breaker when a circuit requires both protections (common in kitchens, laundry areas, unfinished basements, and other locations depending on jurisdiction and circuit type). Benefits include fewer devices in the chain, fewer line/load mistakes, and clearer troubleshooting: if it trips, you know the breaker is the protective point. This is especially helpful when downstream devices include smart receptacles, in-cabinet power supplies, or appliances with electronics that can confuse stacked protection.

Strategy B: AFCI breaker + downstream GFCI receptacle(s)

This is common when only certain outlets on an AFCI-protected circuit require GFCI (for example, a general lighting circuit that also feeds a single receptacle in a location requiring GFCI). It can also be used when you want local reset capability at the point of use. The trade-off is that you now have two protective devices that can trip, and the downstream GFCI must be wired correctly (line vs load) and labeled if it protects downstream receptacles.

Strategy C: GFCI breaker + downstream AFCI (rare in typical dwelling work)

Less common because AFCI is usually implemented at the breaker. If you encounter it in retrofit scenarios, be cautious: adding AFCI downstream of a GFCI sensing point can create unexpected interactions, and troubleshooting becomes more complex.

When to avoid stacking (practical guidance)

- If the circuit serves multiple electronic loads with known leakage (multiple plug-in adapters, AV equipment, network gear), stacking GFCI devices can push you closer to nuisance-trip territory.

- If the homeowner needs simple resets, choose one protective point and make it obvious (labeling, panel schedule, and device labeling).

- If the circuit is critical (sump pump, freezer, medical equipment), follow code allowances for dedicated circuits and protection requirements, and consider alarm/monitoring solutions rather than weakening protection. Avoid “workarounds” that defeat safety devices.

Nuisance Trip Prevention: Root Causes and How to Design Them Out

1) Neutral handling errors (the #1 preventable cause)

Any time a GFCI or dual-function breaker is used, the neutral must return through the breaker’s neutral sensing path. Common mistakes include landing the circuit neutral on the neutral bar instead of the breaker neutral terminal, mixing neutrals between circuits, or sharing a neutral without a 2-pole common-trip device and correct neutral routing. These errors often cause immediate trips when the breaker is turned on or when a load is applied.

Prevention habits:

- Pull neutrals with their circuit conductors and keep them bundled until termination.

- Terminate one circuit at a time: hot, neutral, ground, then torque.

- Use clear circuit IDs on neutral conductors in the panel and in multi-gang boxes.

2) Neutral-to-ground contact downstream

A neutral touching ground downstream of a GFCI sensing point can create parallel return paths and imbalance. This can happen from a nicked neutral contacting a metal box, a device yoke pinching insulation, a miswired receptacle, or an incorrect bonding jumper in a subpanel or accessory enclosure. In smart homes, it can also happen when low-voltage and line-voltage compartments are crowded and conductors get damaged during device insertion.

Prevention habits:

- Use proper box fill and device depth; don’t force devices into tight boxes.

- Inspect for insulation damage at clamps and yokes.

- Keep neutrals isolated from grounds in subpanels and downstream enclosures where bonding is not permitted.

3) Cumulative leakage from electronics and EMI filters

Many electronic power supplies include capacitors to ground for EMI suppression. Each device may leak a small amount of current to ground; a circuit with many devices can approach the GFCI trip threshold. This is common in media centers, kitchens with multiple countertop appliances, and smart-home “utility shelves” where hubs, routers, PoE injectors, and adapters accumulate.

Prevention habits:

- Distribute plug-in power supplies across multiple circuits when feasible.

- Use dedicated circuits for clusters of electronics when code and design allow.

- Prefer hardwired listed power supplies where appropriate, installed per manufacturer instructions, to reduce the “wall-wart pileup.”

4) Load characteristics that resemble arc faults

Some loads generate noise or switching patterns that can be interpreted as arcing, especially at startup. While modern AFCIs are improved, nuisance trips still occur with certain appliances or older equipment. In smart homes, motorized devices and electronically controlled appliances may have variable-speed drives or switching supplies that create complex waveforms.

Prevention habits:

- Use the manufacturer’s recommended breaker type when specified (some appliances specify compatible AFCI/GFCI types).

- Keep terminations tight and conductors properly dressed; loose connections can create real arcing that looks like “nuisance” but is actually a hazard.

- Separate known-problem loads onto dedicated circuits where required/allowed, rather than weakening protection.

5) Shared neutrals and MWBC pitfalls

MWBCs can be code-compliant and efficient, but they require correct handle ties/common-trip and correct neutral routing through the protective device. With GFCI/AFCI sensing, any imbalance due to misrouted neutral or incorrect pairing of hots can trip immediately. Additionally, if a downstream device borrows a neutral from a different circuit (common in remodels), trips become intermittent and hard to reproduce.

Prevention habits:

- Verify MWBC hots are on opposite phases/legs as required so neutral currents cancel properly.

- Use a 2-pole breaker designed for MWBC with the correct neutral pigtail/terminal arrangement.

- During retrofit, positively identify neutrals before separating circuits in multi-gang boxes.

Practical Step-by-Step: A Code-Minded Installation Workflow

Step 1: Map protection requirements by location and function

Create a circuit list that includes: area served, receptacle locations, fixed equipment, and whether AFCI and/or GFCI is required. This is not a full “planning” chapter; the focus here is protection mapping so you don’t discover late that you need to change breaker types or add devices.

- Mark circuits that require both AFCI and GFCI; default to dual-function breakers unless there is a clear reason not to.

- Mark circuits where only certain outlets require GFCI; decide whether to use a GFCI receptacle at the first outlet or a GFCI breaker for the whole circuit.

- Identify critical loads and verify code requirements for their protection; do not assume exemptions.

Step 2: Choose the protective device architecture

For each circuit, decide one of the strategies (dual-function breaker, AFCI breaker + downstream GFCI, etc.). Document the decision in the panel schedule notes so future service is faster.

- If using downstream GFCI receptacles, decide which device is the “first in line” and ensure the feed enters that box.

- If using a GFCI receptacle to protect downstream, plan for labeling (“GFCI Protected” and “No Equipment Ground” if applicable in older retrofits, where permitted).

Step 3: Install with neutral discipline

Neutral discipline is a repeatable set of habits that prevents most nuisance trips.

- In the panel: land the branch neutral only where the breaker design requires (breaker neutral terminal or pigtail to neutral bar). Do not mix neutrals under one terminal unless the terminal is listed for it.

- In boxes: keep neutrals of different circuits physically separated; use wirenuts or connectors rated for the conductor count and type.

- On MWBCs: verify the correct 2-pole device and route the neutral through the same sensing mechanism as the associated hots.

Step 4: Torque and dress conductors to reduce real arcing

Loose terminations can create actual arcing and heat, which will trip AFCIs (as they should). Use a torque screwdriver/wrench per device labeling. Dress conductors so that device installation does not stress terminations or pinch insulation.

Step 5: Commission protection devices before pairing smart features

Before you add complexity (smart modules, controlled loads, automation), verify that the protective layer is stable.

- Test each GFCI function using the built-in test button (breaker and/or receptacle). Confirm reset works and downstream outlets de-energize as expected.

- For AFCI/dual-function breakers, use the test button and verify the breaker trips and resets properly.

- Record results in a commissioning checklist with circuit IDs.

Practical Step-by-Step: Systematic Troubleshooting of Trips

When a customer reports “it keeps tripping,” your goal is to determine whether it is (1) a wiring/installation error, (2) a legitimate fault, or (3) a compatibility/leakage accumulation issue. Use a consistent sequence so you don’t chase symptoms.

Step 1: Identify what tripped and what function likely caused it

- Breaker trip vs receptacle trip: ask the occupant which device they reset.

- Many modern breakers provide trip indication (arc-fault, ground-fault, overcurrent). Use the manufacturer’s legend and interpret it carefully.

- Ask what was operating at the time: appliance start, rain event, cleaning, holiday lighting, etc.

Step 2: Rule out immediate wiring faults

De-energize and inspect the most common wiring issues first.

- Check for shared/mixed neutrals: look for neutrals from different circuits tied together in multi-gang boxes, especially where smart controls were added.

- Check line/load on GFCI receptacles: reversed line/load can cause no reset or unpredictable protection.

- Inspect for neutral-to-ground contact: especially in metal boxes, device yokes, and crowded boxes.

Step 3: Isolate the load vs the branch wiring

Determine whether the trip follows a specific device or is present with everything unplugged/off.

- Unplug all cord-and-plug loads on the affected circuit. Reset and see if it holds.

- If it holds with everything unplugged, add loads back one at a time until the trip recurs. This is the fastest way to identify a leaky or noisy device.

- If it still trips with all loads removed, suspect wiring damage, moisture intrusion, or a neutral/ground issue in fixed wiring.

Step 4: Use appropriate test instruments (and know what each tells you)

- Clamp meter: measure load current and look for unusual spikes during startup. While it won’t directly show leakage, it helps correlate trips with inrush events.

- Insulation resistance tester (megohmmeter): useful for finding leakage paths in fixed wiring or motors (follow equipment guidance; disconnect sensitive electronics before megger testing).

- Receptacle tester: quick polarity/ground presence check, but do not rely on it alone for diagnosing GFCI/AFCI issues.

- Leakage current clamp meter (if available): can measure differential/leakage by clamping both hot and neutral together; any net current indicates leakage. This is valuable for cumulative leakage problems.

Step 5: Address the cause with a code-compliant fix

Examples of code-minded corrective actions:

- Mixed neutrals: separate neutrals by circuit; if MWBC is present, ensure correct 2-pole protection and neutral routing.

- Device-caused leakage: replace the faulty appliance/power supply; if cumulative leakage is the issue, redistribute loads to other circuits (do not upsize trip thresholds or defeat protection).

- Moisture-related trips: correct the source (exterior box sealing, gasket, cover type, conduit sealing) and replace any compromised devices.

- Arc-fault trips from loose terminations: re-terminate with proper stripping, conductor condition, and torque; replace damaged devices or conductors.

Coordination Patterns in Common Smart-Home Scenarios (Without Repeating Device-Selection Basics)

Kitchen small-appliance circuits with many switch-mode loads

Countertop appliances, chargers, and plug-in devices can create cumulative leakage. If both AFCI and GFCI are required, a dual-function breaker often reduces stacked-device interactions. If using GFCI receptacles, keep the number of downstream protected devices reasonable and ensure the first device is accessible for reset.

Laundry and utility areas with motors and dampness risk

Washers, dryers (where applicable), and utility receptacles can combine motor noise and moisture exposure. Expect legitimate GFCI trips if there is insulation breakdown in older equipment. For nuisance prevention, focus on correct wiring, good terminations, and verifying appliance condition rather than changing protection type.

Garage/workshop circuits with intermittent tool loads

Brush motors and switching loads can trip AFCIs in some cases. Keep receptacle circuits properly protected as required, and consider separating “general-use receptacles” from dedicated equipment circuits where permitted. When troubleshooting, reproduce the trip with the specific tool and inspect cords and plugs; many “nuisance” events are damaged cords creating real arcing or leakage.

Outdoor and damp-location smart equipment

Outdoor smart controllers, lighting power units, and receptacles are exposed to moisture and temperature cycling. Nuisance trips often trace back to water ingress, condensation, or deteriorated gaskets. Coordination here is less about electronics and more about enclosure integrity and correct device ratings. Verify that downstream loads are suitable for wet locations and that covers and fittings are installed correctly.

Documentation and Labeling That Prevents Repeat Service Calls

Protection coordination is only as good as the information left behind. When a homeowner or another electrician can quickly identify what is protected by what, troubleshooting time drops dramatically.

- Panel schedule notes: indicate “Dual-function AFCI/GFCI” or “AFCI breaker; GFCI at first receptacle in ____ location.”

- Device labeling: label downstream receptacles protected by a GFCI device where required/expected.

- As-left checklist: record that each protective device was tested, and note any circuits with known sensitive loads (e.g., “treadmill on Circuit 12”).

Field Tips: Small Practices That Make AFCI/GFCI Behave Better

- Keep pigtails neat and short: reduces crowding and the chance of insulation damage in boxes.

- Use listed connectors: especially with mixed conductor types; poor splices can heat and create intermittent faults.

- Separate neutrals in multi-gang boxes: even when allowed to share a box, keep splices organized by circuit.

- Don’t ignore “intermittent” trips: intermittent often means moisture, a failing appliance, or a marginal termination that will worsen.

- Follow breaker manufacturer guidance: some panels require specific breaker families; mixing incompatible breakers can create unreliable behavior and code issues.